By Harv Scholz, P.E. Senior Mechanical Engineer | Pureflow, Inc.

Ultrafiltration, also known as UF, is a class of filtration that uses a membrane, either in the form of a spiral wound element similar to a reverse osmosis membrane, or more often, a tubular element known as a hollow fiber. Other types of membrane filters are Microfiltration (MF), Nanofiltration (NF), and Reverse Osmosis (RO). These differ primarily in the sizes of particles that are excluded from the filtered water. Ultrafiltration and Microfiltration are size-exclusion processes that reject particles, pathogens, and high molecular weight species. UF has pore sizes in the range of 0.001 to 0.1 micron, with a 0.03 nominal micron rating being typical.

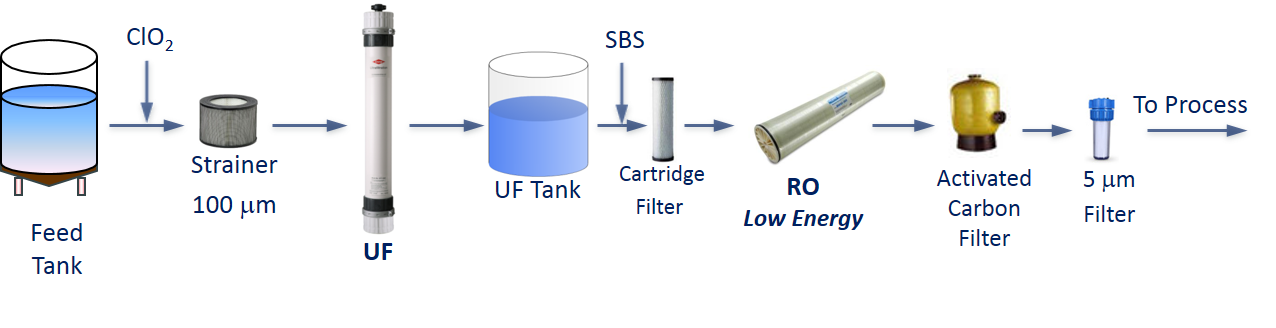

UF is often used as pretreatment to an RO. The UF removes the majority of particulates that fouls an RO, as well as colloids, harmful bacteria, most viruses, and parasites such as cryptosporidium and giardia. The RO removes the remaining bacteria and viruses, dissolved salts, dissolved organics, color, taste, and odor.

UF Benefits to RO Operation

The UF acts as a barrier filter, retaining any particles over 0.1 micron. This allows the RO to operate at a higher design flux and therefore higher total flow, to increase production, or to produce the same flow as before but with less energy. In a new installation, a smaller RO can be used. With UF pretreatment, the RO has reduced requirements for membrane cleaning, meaning that chemical usage and wastewater discharges are reduced. Longer membrane life is also a benefit.

UF Applications

Beverage Water Preparation- UF is used to remove particles, viruses, bacteria, and parasites from city or other source waters used in bottled water or beverage production, usually as feed to an RO.

Ultrapure Water (Semiconductor)- UF is used as a pretreatment to the RO, as a polishing stage in the ultrapure water supply, or for reclaiming process water. When acting as a final barrier, it can remove fine particles (>0.03µ) and microorganisms from water being sent to production.

Drinking Water- UF is used, downstream of clarification, as the final filtration for the surface waters used by many municipalities for drinking water. It reduces turbidity to less than 0.1 NTU, and removes viruses, parasites, and bacteria.

Desalination- UF serves as a fine filtration prior to desalination RO membranes, thereby protecting the membranes and increasing their usable life. Recovery in the UF operation itself is usually higher than 95%.

Recycling- UF can remove most particulates from recoverable rinse waters, process waters, and irrigation waters, providing usable sources of non-potable water.

In all cases, prescreening with a 100-300 micron filter should be provided. If dissolved substances are to be removed, coagulation or oxidation will be required.

UF Description

In a Dow UF the hollow fibers are only 1.3 mm O.D. x 0.7 mm ID and are made from H-PVDF polymer ( H=hydrophilic). These fibers have high resistance to chemicals, heat, and fouling, and are mechanically strong. In the modular design, the hollow fibers are bundled inside a PVC shell, ranging in size from 6.5” to 8.9” OD. These modules are positioned vertically on a skid to form a UF rack that can be pre-piped and pre-wired and ready for installation on-site. (Note: Dow UF is shown for the sake of consistency throughout this discussion. Other brands of UF will vary in design and procedures.) In addition to the hollow fiber modular design, UF is also sold in flat sheet, spiral-wound, plate-and-frame, tubular module, and loose fiber bundle configurations.

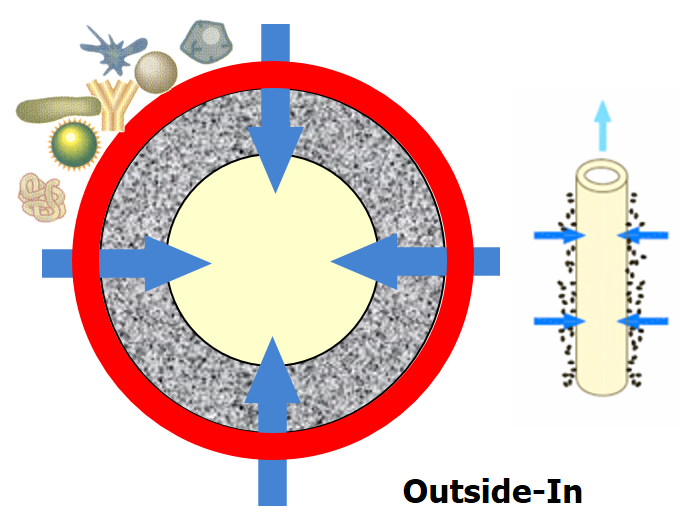

Since the filtration flow path in a Dow UF hollow fiber is outside-to-inside, the contaminants from the feed will accumulate on the outside of the fibers, much like a cartridge filter that is familiar to all water purification. The purified water will flow through the center of the hollow fiber to be collected at the top of each module as filtrate. The outside-in flow as opposed to inside-out has the advantage that the contaminants have more area on the outside of the fiber on which to accumulate, thereby extending the run time between backwashes and cleanings. Also, with flow on the outside and with a vertical design, an air-scour bubbling (upward through the shell on the outside of the fibers) can be used to shake particles loose from the fibers prior to backwash cleanings. So, unlike a cartridge filter in which the elements have to be replaced when they are loaded with contaminants, the UF has permanent elements (hollow fibers) that can be cleaned by backflushes, air scouring, and eventually by stronger CIP operations. This gives the UF a long service life, finer filtration, and much less maintenance than a replaceable filter element.

Flux

UF modules are rated on the amount of permeate they can produce in gallons per square foot per day (gfd). This is known as flux. To size the module for a specific duty, the square feet of a membrane surface must also be known. A Dow SFP-2860XP module has 549 ft² of membrane area and is rated for 24-70 gfd flux, depending on water temperature and turbidity.

Advantages/Disadvantages of UF

Some of the advantages of UF (based on the Dow UF) are:

- 0.03 micron pore size for removal of bacteria (>6 log reduction), viruses (>2.5 log reduction), and particulates (<2.5 SDI)

- Improved and more consistent product quality: ultrafiltrate turbidity less than 0.1 NTU (independent of the raw water turbidity) and SDI less than 2.5

- Dead end flow, meaning that all the feed water goes through the membranes. Recovery at 95% is due to water usage for backwash requirements.

- UF can replace media filtration pre-RO (on relatively clean feedwater), providing higher quality feedwater which results in less cleaning of the downstream RO and requiring a smaller footprint.

- Filtrate flux at max 30 psi transmembrane pressure – 24 -70 gfd (gallons/sq.ft./day)

- Hollow fiber membranes tolerant of temperatures from 1 to 40°C (34 to 104⁰F)

- Typical feed pressure 4 to 90 psi

- Operating pH range 6-9 (2-11 max for cleaning)

- Can tolerate typical chlorine exposure of 0.5 ppm (200 ppm max. continuous exposure, and 2000 ppm max. exposure for cleaning)

- Air-scour enhances cleaning efficiency and improves system recovery

- Filtration and cleaning operations can be highly automated, reducing labor

- Module and skid Integrity Testing can be done easily online to detect potential leakages without significant plant downtime. Membrane modules can be individually isolated for repair, maintenance or replacement without compromising the plant output.

Some disadvantages of UF are:

- Depending on feedwater quality, UF may need frequent backwashing and cleaning

- A leak in a hollow fiber requires an integrity test and a repair of the defective tube (typically blocking it off)

- UF membranes have a service life of 5-7 years, possibly longer, but will require periodic replacement

- A bag filter or automated screen filter (100 – 300 micron) must be used ahead of the UF, to prevent large particles from entering it.

Normal Operation- Filtration Mode

At initial startup the modules are flushed using a Forward Flush to remove any residual chemicals or trapped air. This flush is only on the outside of the fibers and does not create any filtrate. After the forward flush, the modules can be placed in the Operating Mode. An operating cycle is typically 20 to 60 minutes. While operating, the module is in dead-end mode meaning that 100% of the feedwater is converted to filtrate. During this step, contaminants are removed, and transmembrane pressure will rise. At the end of a pre-set time, a backwash cycle is initiated.

Backwash and Chemically Enhanced Backwash

Backwash Mode is set to occur after a specified run-time, and may include an Air Scour. It always includes draining, backwashing through the top drain, backwashing through the bottom drain, and a forward flush. The air scour step, when included, is used to loosen particulates deposited on the outside of the membrane surface. Air is introduced at the bottom of the module and flows along the outside of the fibers. The displaced feed flow/concentrate is allowed to discharge through the top of the module for disposal. After air scour, the module is drained to remove dislodged particles.

A chemically enhanced backwash or CEB can be used if the feedwater quality is bad and the normal backwashes are not effective. Chemicals are added to improve the backwash cleaning ability. CEB is performed every 1-7 days.

Clean-In-Place (CIP)

CIP is on demand, and frequency can range from 1- to 6-month intervals. Backwashes should be done to remove loose particles. The CIP steps are:

- Air scour + backwash to top drain + backwash to bottom drain

- Gravity Drain

- Mix and heat chemical solution to 104°F.

– Acid Cleaning – pH 2, for inorganic fouling

– Alkali Cleaning – pH 12 for organic fouling (repeat entire procedure at high pH)

- Recirculate chemical solution through the module 30-40 min., then soak 60 min., then recirculate again.

- Drain chemical solution, air scour, then backwash and forward flush.

- Purge modules with filtrate and return to service.

Membrane Fouling

During filtration, contaminants will build upon the outsides of the fibers. To remove this, backwashes and CIPs are used. As the Transmembrane Pressure curve shows, some of the fouling is removable by backwashes. Additional fouling can be removed by periodic CIP procedures. However with time, there is always a small amount of irreversible fouling that cannot be removed. As this increases over time, the membrane module will eventually need to be replaced.

Conclusion

Ultrafiltration is a water purification technology that can be used as a pretreatment process prior to RO or other filtration, often replacing the conventional media filtration. Or it can be used as a final treatment for relatively clean feedwaters. It can remove particles, viruses, and pathogens to reduce chemical treatment of drinking water. It can provide a barrier pre-filter to an RO to reduce maintenance on the RO. UF modules should be used cautiously on high turbidity waters due to excessive and difficult-to-remove fouling that would occur. UF in other configurations (such as the submerged type, where bundles of bare fibers are submerged in the turbid water, with flow outside-to-inside via suction) are a better design for this application. In the latter case, UF fiber bundles are physically removed from the turbid water and are cleaned off-line.

While there are many other applications for ultrafiltration, such as in the food industry where they are used for concentrating cheese whey and fruit juices, this paper is directed mainly to ultrafiltration for water purification systems.

Other brands and configurations of UF are available from Pureflow should a user have specific needs.

Click here to view the pdf version.

Harv Scholz is a Senior Mechanical Engineer at Pureflow, Inc. and has been a member of the Pureflow team for over 14 years. Harv has over 32 years of experience in design of mechanical systems, pressure vessels, heat exchangers, piping systems, and storage tanks. Harv has is B.S. from the U.S. Naval Academy and his M.S. in Aerospace Engineering from North Carolina State University.

Article is re-printed with permission of Harv Scholz. Pictures are printed with permission of Dow Chemical Company. Unauthorized reproduction of this article and/or use in any form is strictly prohibited without the expressed written consent of Pureflow, Inc.